The biscuit production process is as follows:

The first step: making dough

Horizontal Dough mixer(For Both Hard Dough and Soft dough):

1). Speed from 25r/min to Max. Speed60r/min, frequency speed

2). Full stainless steel 304#

3). Siemens PLC control system.

The second step: pressing dough in thin dough sheet

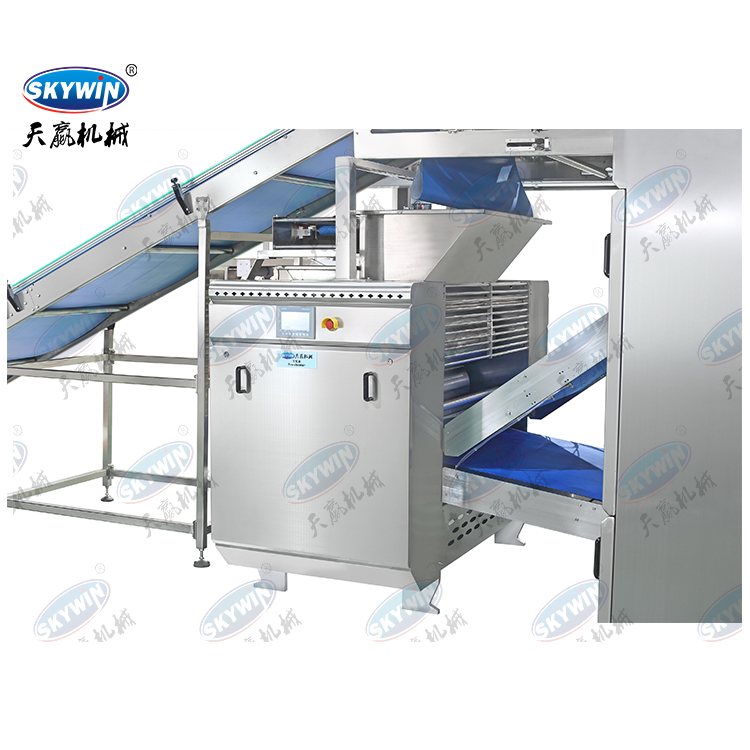

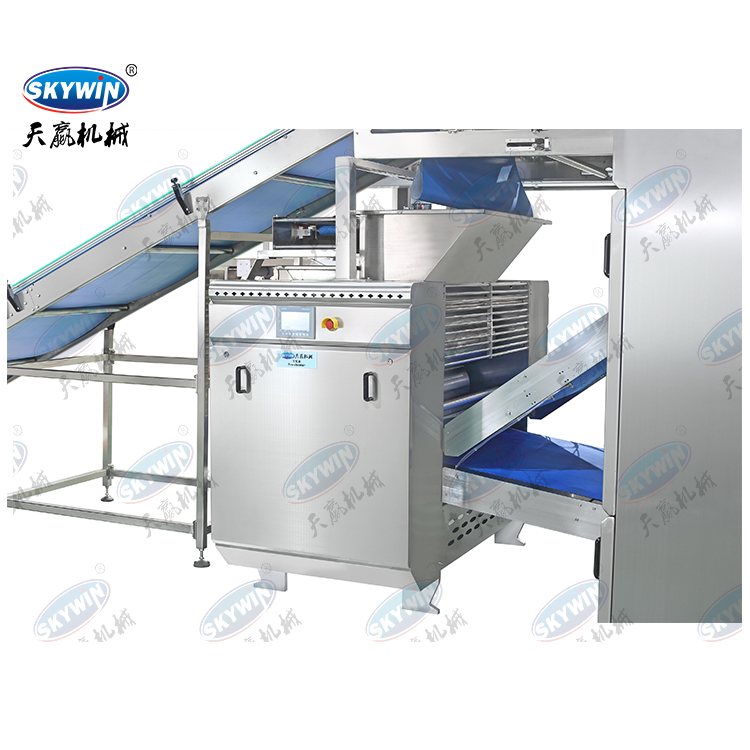

Three Roller Combination Pre-Sheeter:

1). With Feeding Hopper, 304 Stainless steel

2). Food grade PU belt , PU belt has guides groove

3). Groove type feeding roller

4). Siemens inverter and PLC touch screen

5). Dough sheeting thickness can be adjust.

6). Digital display sheet thickness

Horizontal Lanminator (Important For Making Soda Cracker)

1). Gauge rolls quantity 4pcs , 2pcs Groove feeding Gauge roller

diameter, 2pcs smooth type Gauge roller

2). Food grade PU belt width

3). Dough sheeting thickness can be adjust 1-25mm

4).Sheet cutting and laminating 4-12layers

5).Digital display the thickness of sheet

6).Cutting sheet device controlled by Pneumatic device

B/C/D Roller

1). Machine cover 304 Stainless steel

2). Wallboard thickness 30mm

3). Dough sheeting thickness can be adjust Minumun thickness is

0.1mm

The third step: forming biscuit

Twin type Rotary Cutter Panda Biscuit, Cracker Biscuit ... ect

1). with independent driver and speed control

2). Forming mould can be installed printing mould and cutting mould

separately

3). Rotary cutting mould diameter 200mm

4). Siemens inverter and PLC touch screen

5). Machine cover 304 Stainless steel

6). Wallboard thickness 30mm

The fourth step: baking biscuits

Hybrids Direct Gas and Indirect Gas circulation Tunnel oven

1). Temperature 5 zones

2). 9m pre-heating mesh belt

3). 65m divided into 5 temperature zone

4). Siemens inverter and PLC touch screen

5). Air blower for hot wind circulation system

6). Pneumatic automatic tracking and adjust belt and tension

7). Oven cover by 304 Stainless steel

8). Heat resistant material: rock whool

Product packaging

Step 1: Mechanical surface coated with preservative solution (to

protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case / frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement

overall).

♥ Looking Forward To Your Specific Enquires.♥