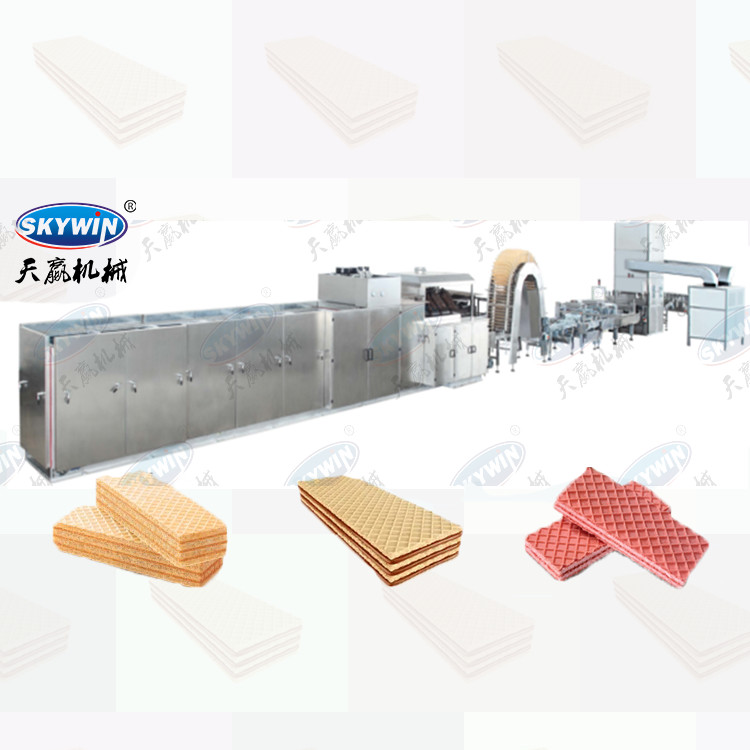

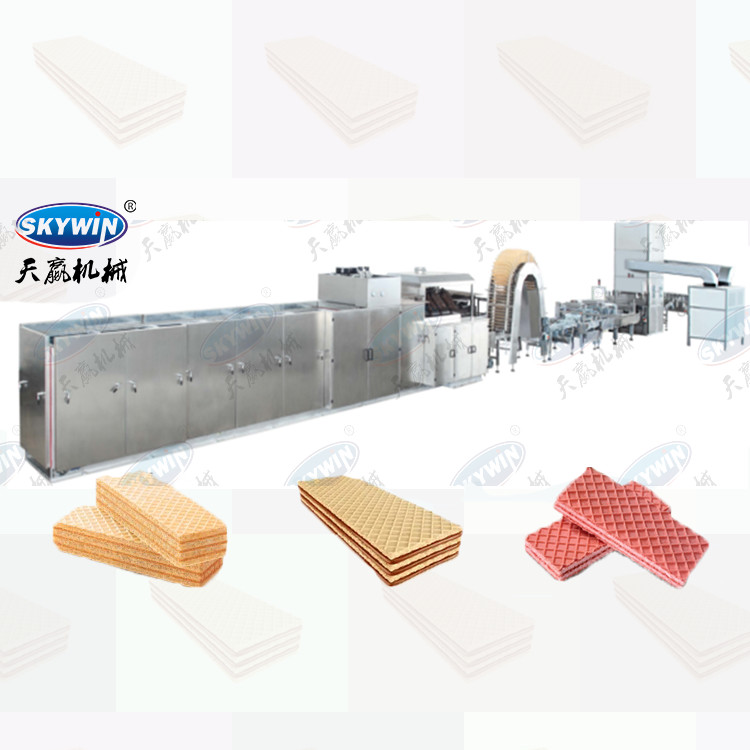

Touch Screen Control Obleas Maker Machine Chocolate Wafer Making

Machine

Product description

Skywin is a new manufacturer specialized in wafer machines, wafer

biscuit production lines, waffle machines.

It is a fully automatic control whole line.

Our factory is the top wafer machine supplier and exporter in

China.

Our gas baking oven has model-27,33,39,45,51,63,75 plates for your

option.

The gas system adopts the Italy Madas brand.

Features of wafer baking equipment

| 1 | The wafer baking system uses LPG or LNG for heating the baking

plates. |

| 2 | The function of the baking oven is fully automatic from spreading

batter on the plates until baked wafer sheets come out of the oven. |

| 3 | Baking is even and produces good quality wafer sheets for the next

procedure. |

| 4 | In PLC there is a PID controller which is used for controlling the temperature of the baking plates automatically. |

| 5 | The collection of the required signal of PID is supplied by an

infrared sensor. |

| 6 | The oven status display and the data reset are supplied by a touch

screen, |

| 7 | all motors have the starting current protection and thermal

overload protection. |

,

Process--Wafer products flow:

The main part of the production line:

1. Baking tunnel oven

This baking oven consists of a batter injection system, gas heating

system and gas leaking alarm system, plates' transferring, and

connecting devices. It is a full metal structure with perfect heat

preservation, with elegant appearance.

2. Cream spreading machine (double head)

Spreading cream on the surface of the wafer sheet by pressing

roller.

The cream hopper with a heating device keeps the hopper

temperature.

3. Cutting and laminating machine

Laminate the wafer sheet and cut the wafer sheet into the wafer bar

as per demand.

4. Multi-grow packing machines

These machines can be connected to wafer cutting machine,

We can design the automatic feeding and packing plant according to

the output.

5. Various wafer samples from the baking machine:

6. Extra machine: Chocolate coating machine to make chocolate wafer

bars

Packaging & shipping

Our regular packaging is multilayer packing, safe transport,

shipping by sea:

Step 1: Mechanical surface coated with preservative solution (to

protect stainless steel).

Step 2: The plastic cushion packing machine (prevent bump).

Step 3: Plastic film packaging (to prevent ventilation).

Step 4: Wooden case/ frame packaging (easy to transport).

Step 5: Tie the bandage outside of the wooden case (reinforcement

overall).

♥Looking Forward To Your Specific Enquires.♥

Skywin Foodstuff Machinery Co. Ltd